INTRODUCTION

XSG Series Chemical Powder Flash Dryer is a new type of drying equipment successfully developed by our factory on the basis of introducing and absorbing foreign technology. This machine has advanced technology, reasonable design, compact structure, wide application range, large production capacity, good product quality, high efficiency, and energy saving. It can be dried, crushed and screened in one equipment at one time, eliminating environmental pollution, and the performance of the whole machine is up to International advanced technology level.

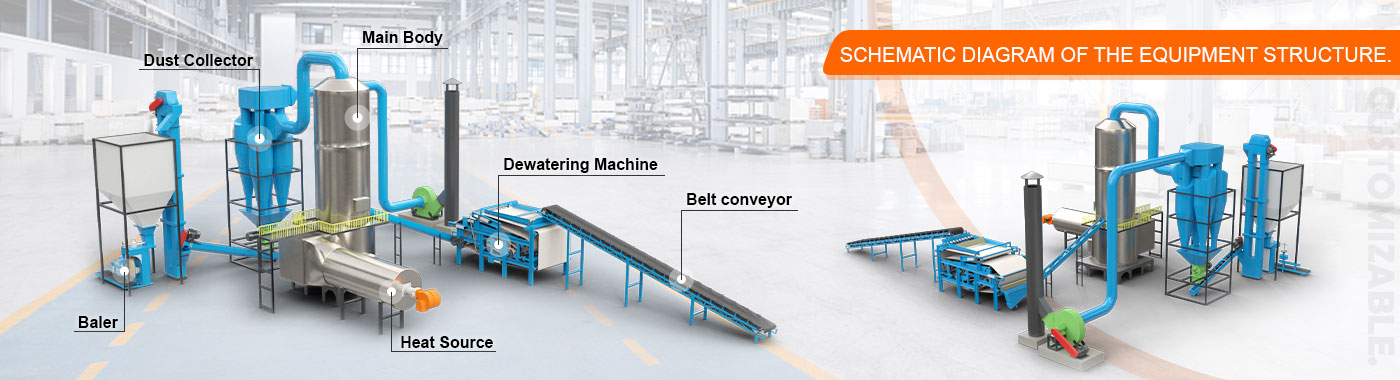

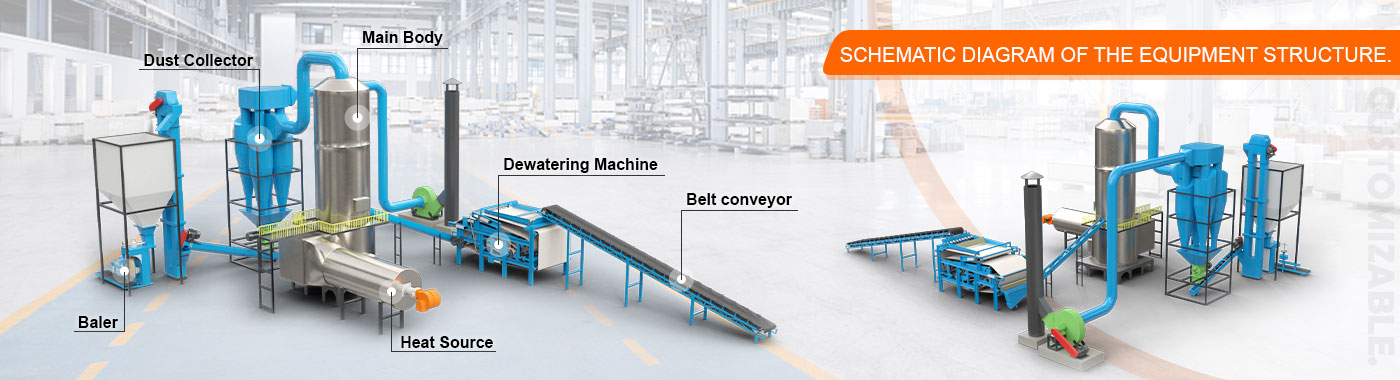

WORKING PRINCIPLE

Hot air goes into the bottom of the dry through an entrance pipe with an appropriate speed,and drives stirring and drying chamber.The air flow brings strong shearing,blowing,floating,and revolving to granulated,collide and rub.Materials become small particles and easy to transfer the heat.Heavy wetter particles got granulated,small particles is brought up by air flows and get dry further in this process.In this rotary motion of gas solid two phase fluid makes the solid particle separated from the gas flow by centrifugal force,the relative speed between gas and solid is very high,therefore the heat transmission is more effective and great heat released in the process.

APPLICATIONS

1.Organic Compounds: atrazine (pesticides), cadmium laurate, benzoic acid, germicide, sodium oxalate, cellulose acetate, the organic pigments,and so on;

2.Dye: santhraquinone, black iron oxide, indigo pigments, butyric acid, titanium hydroxide, zinc sulfide, various azo intermediate;

3.Inorganic: borax, calcium carbonate, hydroxide, copper sulfate, ferric oxide, barium carbonate, antimony trioxide, all kinds of metallic hydroxide,all kinds of heavy metal,salt, synthetic cryolite and so on;

4.Food: soy protein, gelatinized starch, distillers' grains, triticin, wheat starch and so on.

REATURES

Options of feeders make sure continuous and stable feeding,so phenomenon of bridging won’t come up.

Set up the special cooling device in the desiccator bottom has prevented the suppliers from producing the rotten phenomenon in the high temperature district of the bottom.

Special atmospheric pressure seal installation and bearing cool the device,the service life of the running part of effective extension.

Special points of wind device have reduced the obstruction of the equipment,and have offered the wind amount of treatment of the desiccator effectively.

Dry room equips with hierarchical ring and swirl slice,suppliers detailed degree and end moisture content adjustable.(Such as calcium carbonate end but from regulator to moisture content.1%)

As to other dry methods,can increase the proportion of the suppliers effectively.

Circumference speed is high in the drying chamber,the time of material staying is short in order to prevent sticking on the inner wall and to prevent material deterioration.It is high efficient,fast,small space occupancy and great production capacity.