INTRODUCTION

This machine combines the whirl technology with the fluidity .ejection and smashing step technologies. The equipment is compact and small in size ,high in production efficiency and continuous in the production .It has realized that ’a small equipment can perform the large production. The drying capacity for this machine is big but its energy consumption is low .its hear efficiency can go up to more than 70%.

The materical star time is very short .The quality of the final products is very good ,The machine can be used for drying the hest sensitive materials. For the negative pressure or the micro-negative pressure operation ,the machine is good for its tightness and high in the efficiency so as to eliminate the environmental pollution.

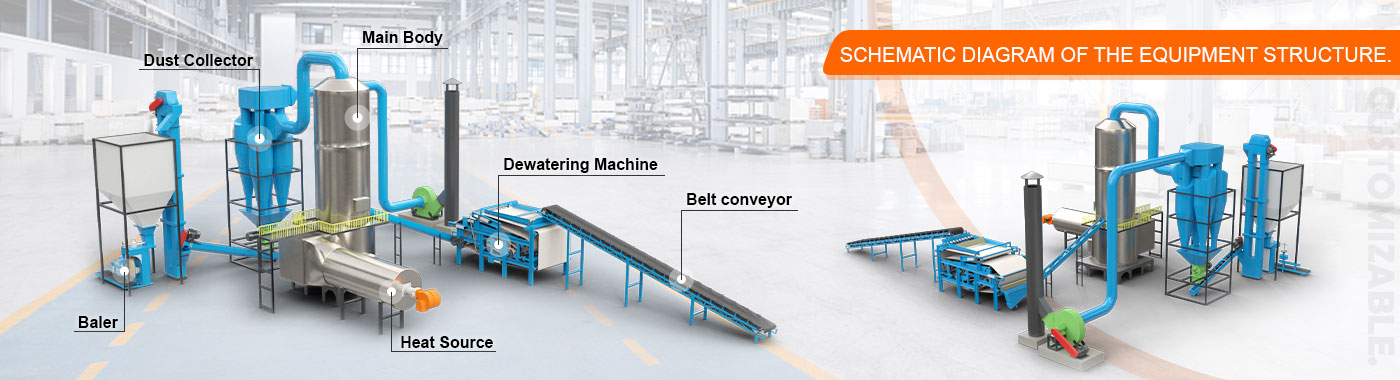

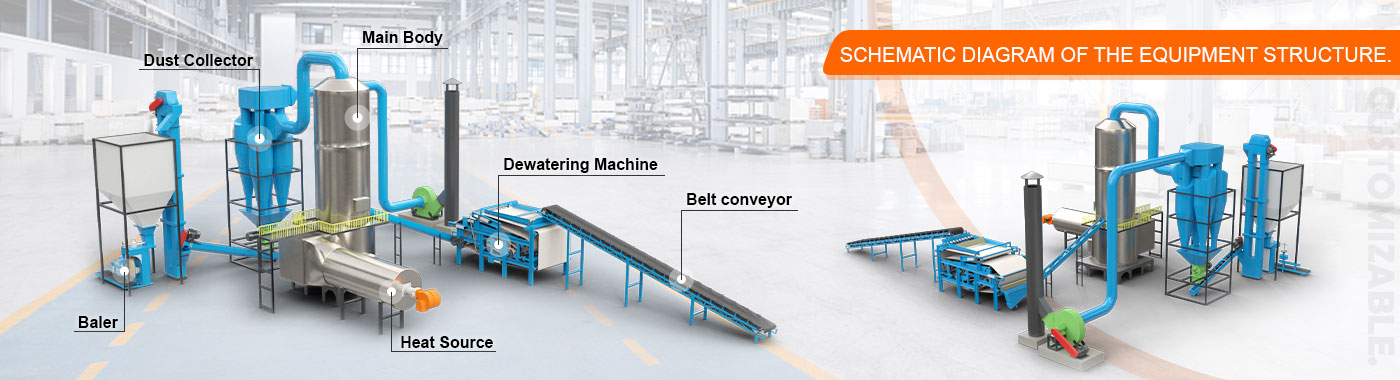

WORKING PRINCIPLE

Wet material is dispersed into a stream of heated air (or gas) which conveys it through a drying duct. Using the heat from the airstream, the material dries as it is conveyed. Product is separated using cyclones, and/or bag filters. Typically, cyclones are followed by scrubbers or bag filters for final cleaning of the exhaust gases to meet current emission requirements.

APPLICATIONS

1.Organic Compounds: atrazine (pesticides), cadmium laurate, benzoic acid, germicide, sodium oxalate, cellulose acetate, the organic pigments,and so on;

2.Dye: santhraquinone, black iron oxide, indigo pigments, butyric acid, titanium hydroxide, zinc sulfide, various azo intermediate;

3.Inorganic: borax, calcium carbonate, hydroxide, copper sulfate, ferric oxide, barium carbonate, antimony trioxide, all kinds of metallic hydroxide,all kinds of heavy metal,salt, synthetic cryolite and so on;

4.Food: soy protein, gelatinized starch, distillers' grains, triticin, wheat starch and so on.

REATURES

Organic combination of swirling, fluidizing, spraying and pulverizing and grading techniques.

Compact equipment, small size, high production efficiency, continuous production, and realize "small equipment, large production".

Large drying strength, low energy consumption and high thermal efficiency.

The material has short residence time and good finished product quality, which can be used for drying heat sensitive materials.

Negative pressure or micro-negative pressure operation, good air tightness, high efficiency and elimination of environmental pollution.