INTRODUCTION

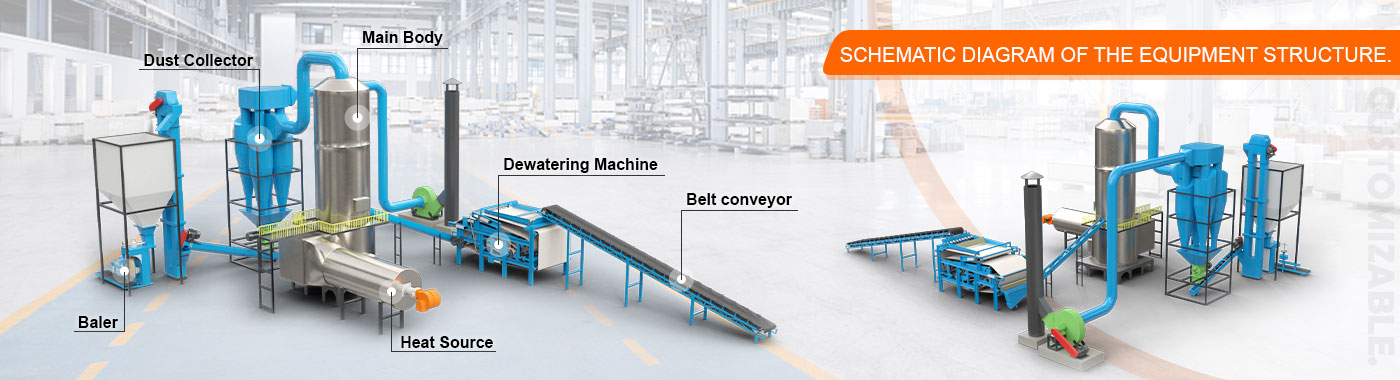

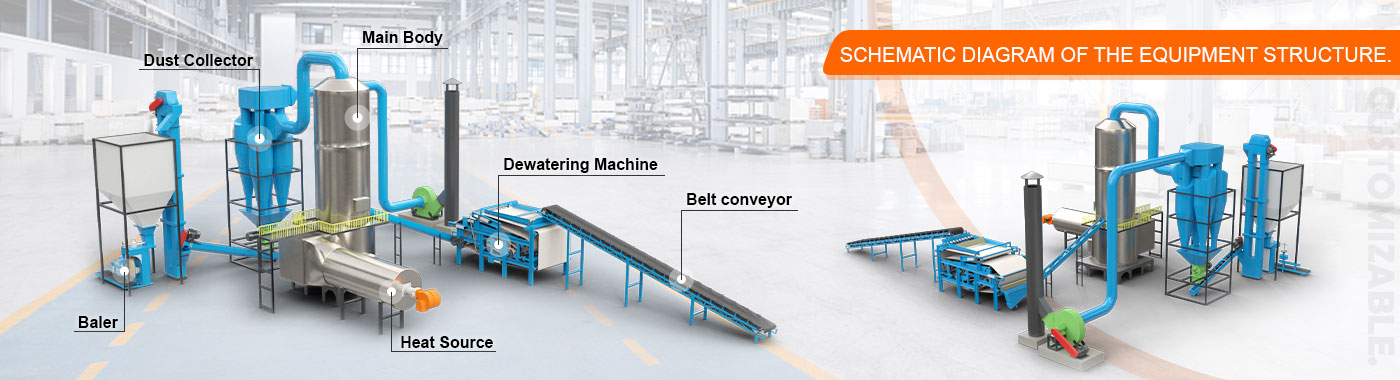

Blood Meal Flash dryer is a new type of drying equipment successfully developed by our factory on the basis of introducing and absorbing foreign technology. This machine has advanced technology, reasonable design, compact structure, wide application range, large production capacity, good product quality, high efficiency, and energy saving. It can be dried, crushed and screened in one equipment at one time, eliminating environmental pollution, and the performance of the whole machine is up to International advanced technology level.

WORKING PRINCIPLE

The clean air heated by the heat exchanger is blown into the air inlet, screwed into the annular gap at the bottom of the drying chamber at an appropriate speed, and then enters the drying chamber in the tangential direction, and rises in a spiral shape: at the same time, the material can be stepless The speed-adjustable feeder is quantitatively added into the tower. In the drying tower, the material and hot air undergo sufficient and efficient mass-to-heat conversion. The dried powdery material is transported to the separator along with the hot air, where the finished product is collected and packaged, and the tail gas is further processed by the dust removal device and emptied.

APPLICATIONS

(1) Inorganic substances: borax, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, magnesium sulfate, antimony trioxide, various heavy metal salts, synthetic cryolite, magnesium carbonate, aluminum oxide, aluminum hydroxide, white carbon black Wait.

(2) Organic matter: atrazine (pesticides), lauric acid, benzoic acid, benzoic acid, bactericide, sodium oxalate, cellulose acetate, etc.;

(3) Ceramics: kaolin, silica, clay, etc.;

(4) Dyestuff: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various azo dye intermediates.

(5)Food: soy protein, starch, distiller's grains, wheat sugar, wheat starch, etc.