INTRODUCTION

Inorganic Compounds Flash Dryer is a new type of drying equipment successfully developed by our factory on the basis of introducing and absorbing foreign technology. This machine has advanced technology, reasonable design, compact structure, wide application range, large production capacity, good product quality, high efficiency, and energy saving. It can be dried, crushed and screened in one equipment at one time, eliminating environmental pollution, and the performance of the whole machine is up to International advanced technology level.

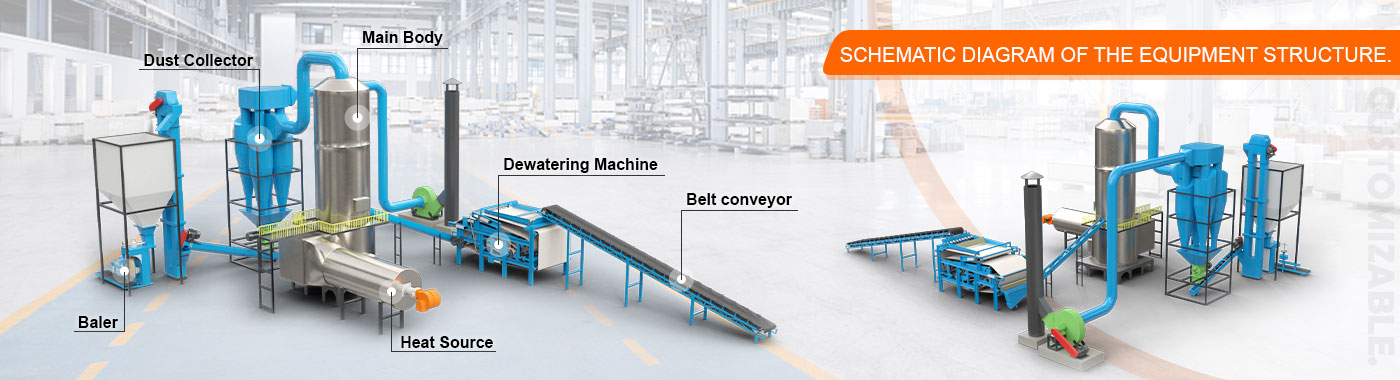

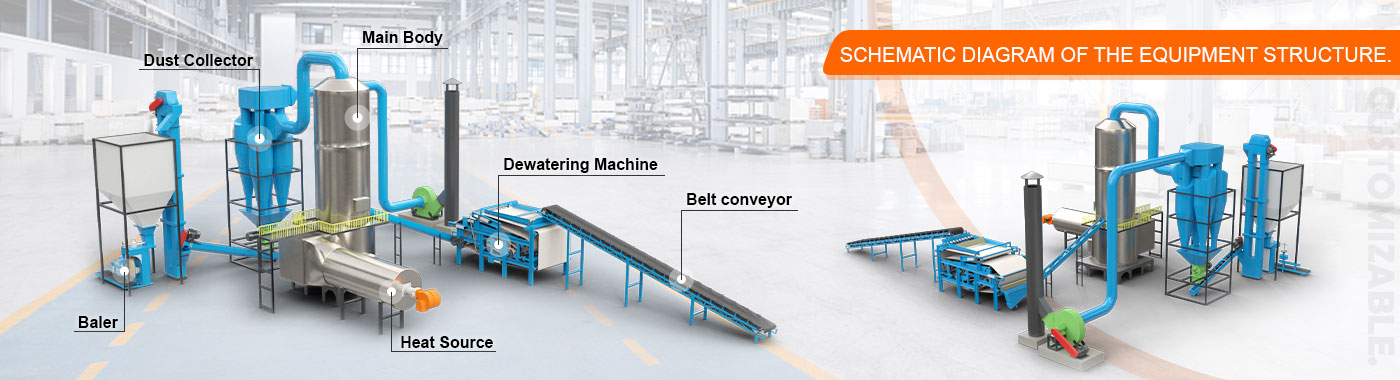

WORKING PRINCIPLE

Hot air enters the stirring part of drying chamber from the bottom, material is stirred by stirring device and then the hot air exerts strong shearing, blowing, floating and rotating effect to material. Therefore material is crushed by centrifugal, shearing, impacting and friction effect. It strengthens the heat exchanging process. In the bottom of drying chamber, big and damp granules are crushed by stirring device, the particles with low moisture content and small size are lifted by rotary air stream, and be further dried. Gas and solid two phases rotary flow, inertia of solid phase is bigger than gas phase, the relative velocity between gas phase and solid phase is high, heat exchanging efficiency is strengthened, so the drying intensity of this machine is high.

APPLICATIONS

XSG rotating flash drying machine is applicable to dry viscous, thixotropic, thermosensitive powdery and granular materials in the dyes, pigment, chemical, ceramics, food and pharmaceutical industry. The appropriate materials can be dried by this drying equipment include:

1. Inorganic materials: boric acid, calcium carbonate, hydroxide, copper sulfate, ferric oxide, barium carbonate, antimony trioxide, metal hydroxide, heavy metallic salt and compound cryolite.

2. Organic materials: atrazine, lauric acid, benzoic acid, sodium oxalate, cellulose acetate

3. Ceramics: kaolin, silica and calay

4. Dyes: anthraquinone, black iron oxide, butyrate, titanium hydroxide, zinc sulfide, azo dyes

5. Food: soy protein, gelatinized starch, vinasse, triticin, wheat starch

6. Pharmaceuticals: analgin (The first domestic application of flash dryer)

REATURES

Many kinds of feeding equipment for choosing, and feeding is continue and static.

Set up the special cooling device in the dryer bottom, has prevented raw material to turn carbonized and change color in the high temperature district of the bottom.

Special atmospheric pressure seal installation and bearing cool the device, the service life of the running part is extended effectively.

Special points of wind device, has reduced the obstruction of the equipment, and has offered the wind amount of treatment of the dryer effectively.

Dry room equip with hierarchical ring and swirl slice, supplies detailed degree and final moisture content adjustable (Such as calcium carbonate the final moisture can adjust to less than 0. 1%).

Compared to other dry methods, it can increase the specific gravity of raw material effectively.

Because gas speed at circle inside the drying chamber is high, the staying time of raw material is short, it prevents the materials stay on the wall of the dyer chamber and the material turn deteriorate effectively, reach high-efficient, fast, little equipment, great production.